|

| December 26, 2018 | Volume 14 Issue 48 |

Motion Control News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Overhung load adaptors provide load support and contamination protection

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Overhung load adaptors (OHLA) provide both overhung radial and axial load support to protect electrified mobile equipment motors from heavy application loads, extending the lifetime of the motor and alleviating the cost of downtime both from maintenance costs and loss of production. They seal out dirt, grime, and other contaminants too. Zero-Max OHLAs are available in an extensive offering of standard models (including Extra-Duty options) for typical applications or customized designs.

Learn more.

Why choose electric for linear actuators?

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Tolomatic has been delivering a new type of linear motion technology that is giving hydraulics a run for its money. Learn the benefits of electric linear motion systems, the iceberg principle showing total cost of ownership, critical parameters of sizing, and conversion tips.

Get this informative e-book. (No registration required)

New AC hypoid inverter-duty gearmotors

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Bodine Electric Company introduces 12 new AC inverter-duty hypoid hollow shaft gearmotors. These type 42R-25H2 and 42R-30H3 drives combine an all-new AC inverter-duty, 230/460-VAC motor with two hypoid gearheads. When used with an AC inverter (VFD) control, these units deliver maintenance-free and reliable high-torque output. They are ideal for conveyors, gates, packaging, and other industrial automation equipment that demands both high torque and low power consumption from the driving gearmotor.

Learn more.

Next-gen warehouse automation: Siemens, Universal Robots, and Zivid partner up

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Universal Robots, Siemens, and Zivid have created a new solution combining UR's cobot arms with Siemens' SIMATIC Robot Pick AI software and Zivid's 3D sensors to create a deep-learning picking solution for warehouse automation and intra-logistics fulfillment. It works regardless of object shape, size, opacity, or transparency and is a significant leap in solving the complex challenges faced by the logistics and e-commerce sectors.

Read the full article.

Innovative DuoDrive gear and motor unit is UL/CSA certified

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

The DuoDrive integrated gear unit and motor from NORD DRIVE-SYSTEMS is a compact, high-efficiency

solution engineered for users in the fields of intralogistics, pharmaceutical, and the food and beverage industries. This drive combines a IE5+ synchronous motor and single-stage helical gear unit into one compact housing with a smooth, easy-to-clean surface. It has a system efficiency up to 92% and is available in two case sizes with a power range of 0.5 to 4.0 hp.

Learn more.

BLDC flat motor with high output torque and speed reduction

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Portescap's 60ECF brushless DC slotted flat motor is the newest frame size to join its flat motor portfolio. This 60-mm BLDC motor features a 38.2-mm body length and an outer-rotor slotted configuration with an open-body design, allowing it to deliver improved heat management in a compact package. Combined with Portescap gearheads, it delivers extremely high output torque and speed reduction. Available in both sensored and sensorless options. A great choice for applications such as electric grippers and exoskeletons, eVTOLs, and surgical robots.

Learn more and view all the specs.

Application story: Complete gearbox and coupling assembly for actuator system

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Learn how GAM engineers not only sized and selected the appropriate gear reducers and couplings required to drive two ball screws in unison using a single motor, but how they also designed the mounting adapters necessary to complete the system. One-stop shopping eliminated unnecessary components and resulted in a 15% reduction in system cost.

Read this informative GAM blog.

Next-gen motor for pump and fan applications

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

The next evolution of the award-winning Aircore EC motor from Infinitum is a high-efficiency system designed to power commercial and industrial applications such as HVAC fans, pumps, and data centers with less energy consumption, reduced emissions, and reduced waste. It features an integrated variable frequency drive and delivers upward of 93% system efficiency, as well as class-leading power and torque density in a low-footprint package that is 20% lighter than the previous version. Four sizes available.

Learn more.

Telescoping linear actuators for space-constrained applications

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Rollon's new TLS telescoping linear actuators enable long stroke lengths with minimal closed lengths, which is especially good for applications with minimal vertical clearance. These actuators integrate seamlessly into multi-axis systems and are available in two- or three-stage versions. Equipped with a built-in automated lubrication system, the TLS Series features a synchronized drive system, requiring only a single motor to achieve motion. Four sizes (100, 230, 280, and 360) with up to 3,000-mm stroke length.

Learn more.

Competitively priced long-stroke parallel gripper

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

The DHPL from Festo is a new generation of pneumatic long-stroke grippers that offers a host of advantages for high-load and high-torque applications. It is interchangeable with competitive long-stroke grippers and provides the added benefits of lighter weight, higher precision, and no maintenance. It is ideal for gripping larger items, including stacking boxes, gripping shaped parts, and keeping bags open. It has high repetition accuracy due to three rugged guide rods and a rack-and-pinion design.

Learn more.

Extend your range of motion: Controllers for mini motors

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

FAULHABER has added another extremely compact Motion Controller without housing to its product range. The new MC3603 controller is ideal for integration in equipment manufacturing and medical tech applications. With 36 V and 3 A (peak current 9 A), it covers the power range up to 100 W and is suitable for DC motors with encoder, brushless drives, or linear motors.

Learn more.

When is a frameless brushless DC motor the right choice?

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

Frameless BLDC motors fit easily into small, compact machines that require high precision, high torque, and high efficiency, such as robotic applications where a mix of low weight and inertia is critical. Learn from the experts at SDP/SI how these motors can replace heavier, less efficient hydraulic components by decreasing operating and maintenance costs. These motors are also more environmentally friendly than others.

View the video.

Tiny and smart: Step motor with closed-loop control

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Nanotec's new PD1-C step motor features an integrated controller and absolute encoder with closed-loop control. With a flange size of merely 28 mm (NEMA 11), this compact motor reaches a max holding torque of 18 Ncm and a peak current of 3 A. Three motor versions are available: IP20 protection, IP65 protection, and a motor with open housing that can be modified with custom connectors. Ideal for applications with space constraints, effectively reducing both wiring complexity and installation costs.

Learn more.

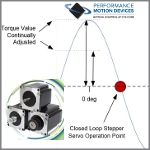

Closed loop steppers drive new motion control applications

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

According to the motion experts at Performance Motion Devices, when it comes to step motors, the drive technique called closed loop stepper is making everything old new again and driving a burst of interest in the use of two-phase step motors. It's "winning back machine designers who may have relegated step motors to the category of low cost but low performance."

Read this informative Performance Motion Devices article.

Intelligent compact drives with extended fieldbus options

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

The intelligent PD6 compact drives from Nanotec are now available with Profinet and EtherNet/IP. They combine motor, controller, and encoder in a space-saving package. With its 80-mm flange and a rated power of 942 W, the PD6-EB is the most powerful brushless DC motor of this product family. The stepper motor version has an 86-mm flange (NEMA 34) and a holding torque up to 10 Nm. Features include acceleration feed forward and jerk-limited ramps. Reduced installation time and wiring make the PD6 series a highly profitable choice for machine tools, packaging machines, or conveyor belts.

Learn more.

Wind tunnel and lasers provide hypersonic proving ground at Sandia National Laboratories

Aerospace engineer Steven Beresh, left, and technologist Russell Spillers of Sandia National Laboratories' aerosciences department place a model in the hypersonic wind tunnel's test section. [Photo by Randy Montoya]

It's about speed, and Sandia National Laboratories, with a hypersonic wind tunnel and advanced laser diagnostic technology, is in an excellent position to help U.S. defense agencies understand the physics associated with aircraft flying five times the speed of sound.

With potential adversaries reporting successes in their own programs to develop aircraft that can be flown at Mach 5 or greater speeds, U.S. development of autonomous hypersonic systems is a top defense priority.

That has made aerospace engineer Steven Beresh of Sandia's aerosciences department and his colleagues at the hypersonic wind tunnel popular as of late.

"Before, the attitude was that hypersonic flight was 30 years away and always will be," said Beresh, the lead wind tunnel engineer. "Now with the national needs, it needs to be tomorrow. We're becoming very busy."

Cold in the tunnel

There's a whoosh of air, then a rumble followed by an electrical hum. It lasts about 45 seconds as air blows down the tunnel to a vacuum at speeds of Mach 5, 8, or 14, depending on pressure settings. The Mach 5 nozzle uses high-pressure air (nitrogen plus oxygen). Nitrogen alone is used at the higher speeds and can be pressurized to 8,600 psi. For comparison, recommended pressure for a car tire is usually between 30 and 35 psi. There is so much potential energy, nitrogen must be stored in a bunker behind 1-ft-thick walls.

A model -- usually shaped like a cone, cylinder, or tailpiece replica of what might be used with flight vehicles -- is placed in the tunnel's 18-in.-diameter test section. By necessity, the model, 4 to 5 in. in diameter, is not an exact replica of the full-scale version but can handle a variety of instrumentation, geometry changes, and spin testing. Part of the wind tunnel engineer's job is to understand those scaling issues.

Inside the test section, temperatures can get extremely low, so electric resistance heaters unique to each Mach number heat the gases and prevent condensation of the gas. Without heat, the air or nitrogen turns to ice in the wind tunnel. The heaters essentially work like very large hair dryers -- 3-MW hair dryers -- that can raise the air temperature above 2,000 F at the beginning of the tunnel. By the time air or gases get to the test chamber, the temperature can fall as low as -400 F.

Physics at hypersonic speeds

When discussing Sandia's contribution to hypersonic research, Beresh refers to solving the "hypersonics problem," which is basically trying to grasp the physics of how air flows over an object at speeds greater than Mach 5.

"The physics are enormously difficult at hypersonic speed," Beresh said. The air and gases react differently than at subsonic speed, materials are put under extreme temperatures and pressure, and there is the added challenge of guidance mechanisms also needing to withstand those pressures.

"We have some information, but not enough information," he said. "We've mostly been dealing with re-entry vehicles. Before, the idea was to just have the vehicle survive; now, it needs to thrive. We're trying to fly through it."

A major strength of hypersonic research at Sandia is the team of people. "To really make an impact in hypersonic research, it requires a collaboration between people who understand the hypersonic vehicle, people who understand the fluid dynamics, people who understand the measurement science, and people who understand the computer simulations," said Daniel Richardson, a mechanical engineer in diagnostic sciences. "That's how you can begin to understand the underlying physical phenomena."

Marriage of measurements

"It's the marriage of these measurements with the wind tunnel capabilities that gives Sandia its national niche," Beresh said. "And you've got to have people who can do both working together."

"Sandia has been at the forefront of developing new measurement techniques," Richardson said. "We're always pushing to improve measurement capabilities."

Sandia is using advanced lasers to measure the speed of the gases passing over the model, direction of air flow, pressure and density of the gases, and how heat is transferred to the model.

Daniel Richardson, left, a mechanical engineer in Sandia National Laboratories' diagnostic sciences, and Yibin Zhang, a postdoctoral fellow, observe a laser that records measurements in the hypersonic wind tunnel. [Photo by Randy Montoya]

"Sometimes it's about how close can you get to the surface of the object to see how gases are reacting at that speed," Richardson said. "Not just in front of the model, but behind it. The ultimate goal is to measure everything, everywhere, all the time."

Freezing time

A laser aimed through the test section's rectangular window allows the light coming in to measure the air flow inside. In recent years, new measurement capabilities have become possible with the commercialization of lasers that operate on femtosecond time scales. That's equivalent to 10-15 seconds, or 1 millionth of 1 billionth of a second.

"These laser pulses are very short in time, but have really high intensity," Richardson said. "At the femtosecond time scale, almost all motion is stopped, or frozen." By coupling the femtosecond laser to a high-speed camera, measurements can be performed thousands of times a second.

"This cutting-edge equipment allows Sandia to extract more data from each wind tunnel run than previously possible," Richardson said.

Develop and validate

Sandia's hypersonic wind tunnel is relatively cheap to use in comparison with larger tunnels at NASA or the Air Force, but tests can go a long way to developing modeling and simulation capabilities. It blends the experimental with the computational to push the science forward, Beresh and Richardson said.

Sandia's wind tunnels have a long history of contributing to the nation; the labs' first was built in 1955. Even in today's era of computational simulation for engineering practice, wind tunnels are key to aerospace technology.

"We are making more accurate measurements because we're always trying to push that capability," Richardson said. "The hypersonic wind tunnel and measurement science are important parts of research at Sandia. It's a proving ground for future capability."

Source: Sandia

Published December 2018

Rate this article

View our terms of use and privacy policy